Team 696 | Our Team

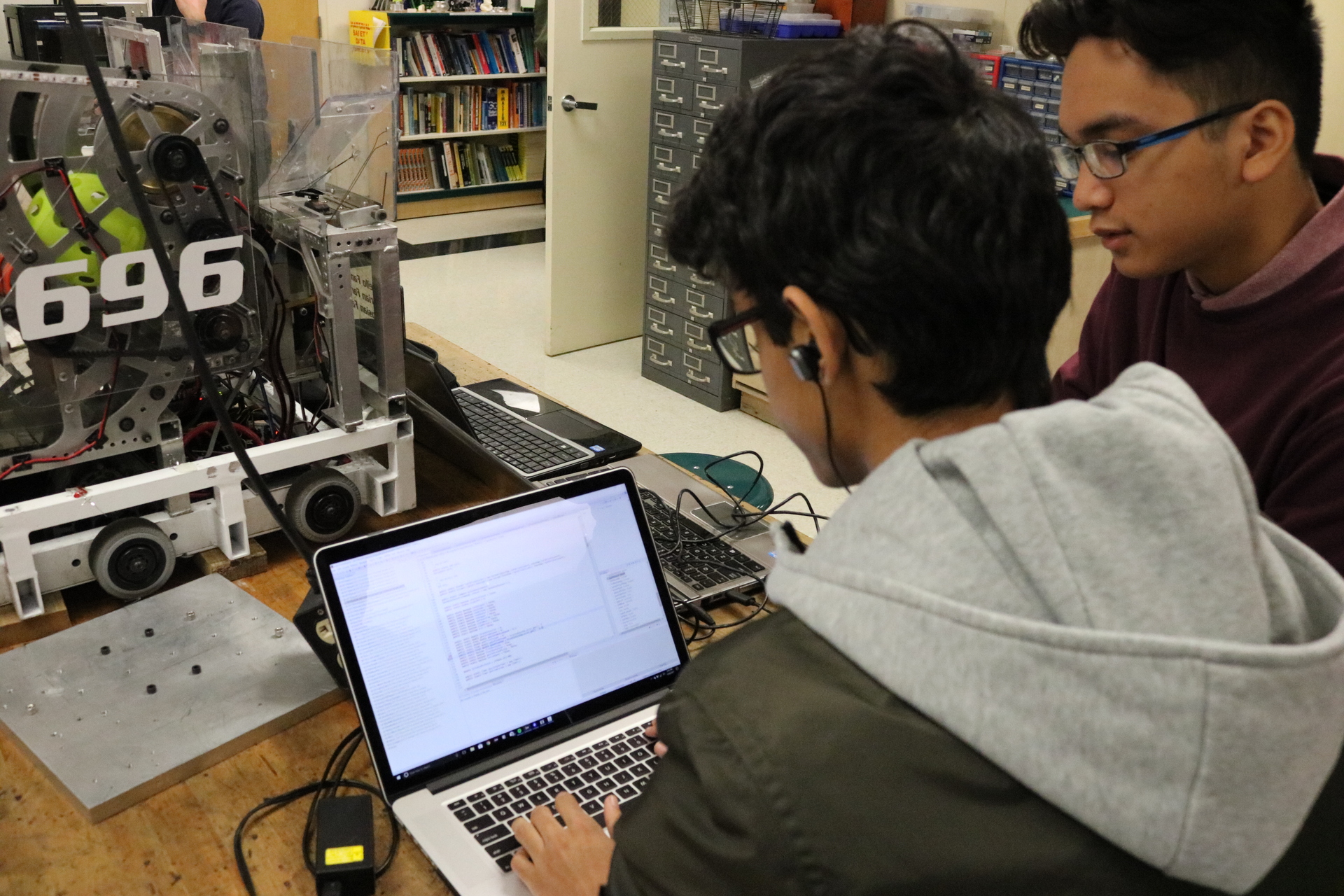

Programming

More than just one‐liners.

The hardware of our robots only tell half the story. Team 696's Programming Team strives to write the most efficient autonomous and teleop code possible, allowing our robots to perform well in competition.

Prototyping

It all starts with a sketch.

From a sketch to a part. Here at Team 696, it's a process that combines attention to detail, careful planning, and dedication towards a common goal: a robust final product.

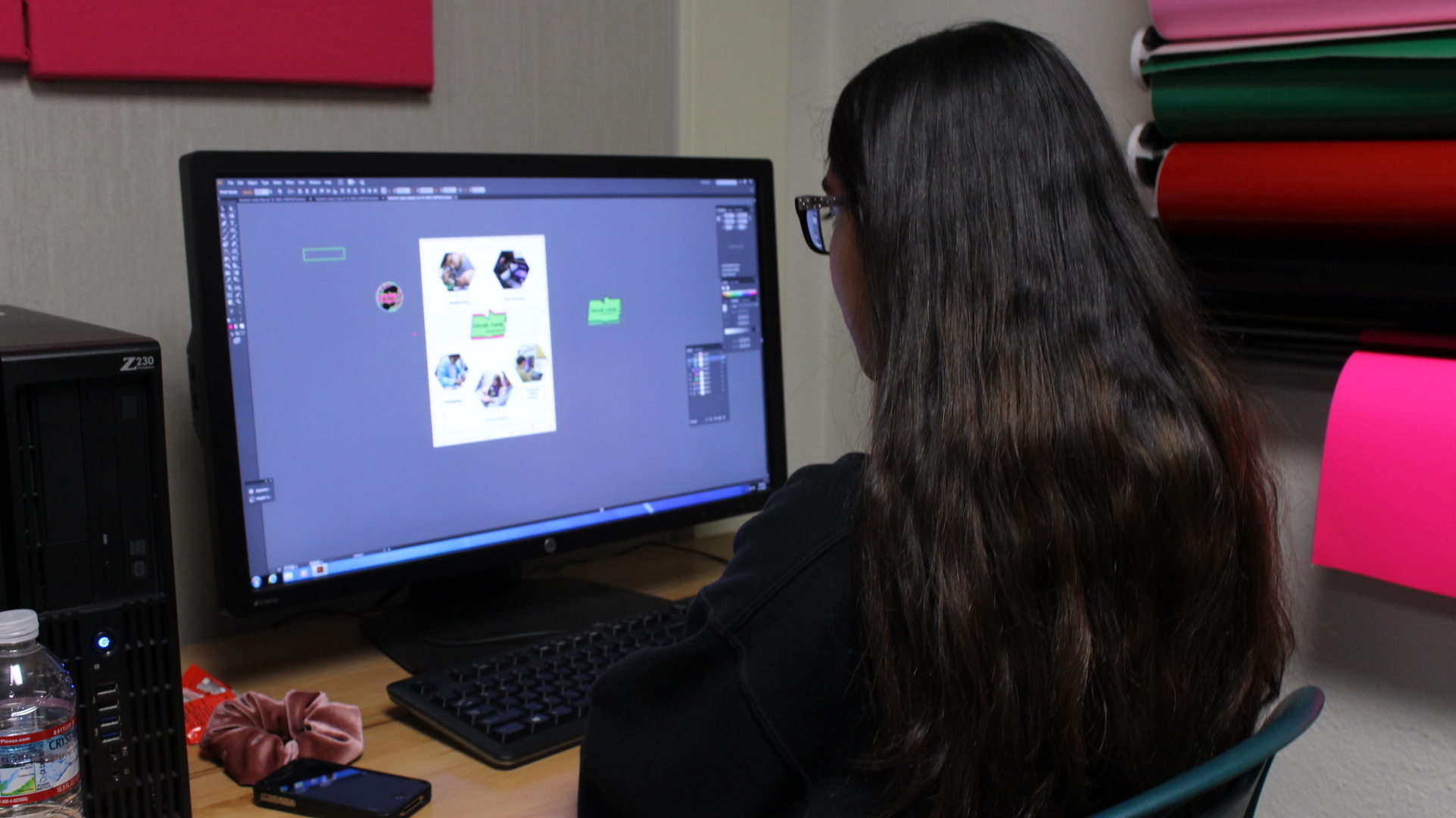

Web and Media

The crossroads between art and tech.

"Industrial design" isn't the only kind of design Team 696 aims to be known for. Our recent emphasis on a higher standard in our media is in an effort to match the quality of our robots.

Business

Finances in check.

Without our business team, Team 696 would simply be unable to continue operating. Funds given to our team ensure that future generations of students will be able to be enriched by Team 696.

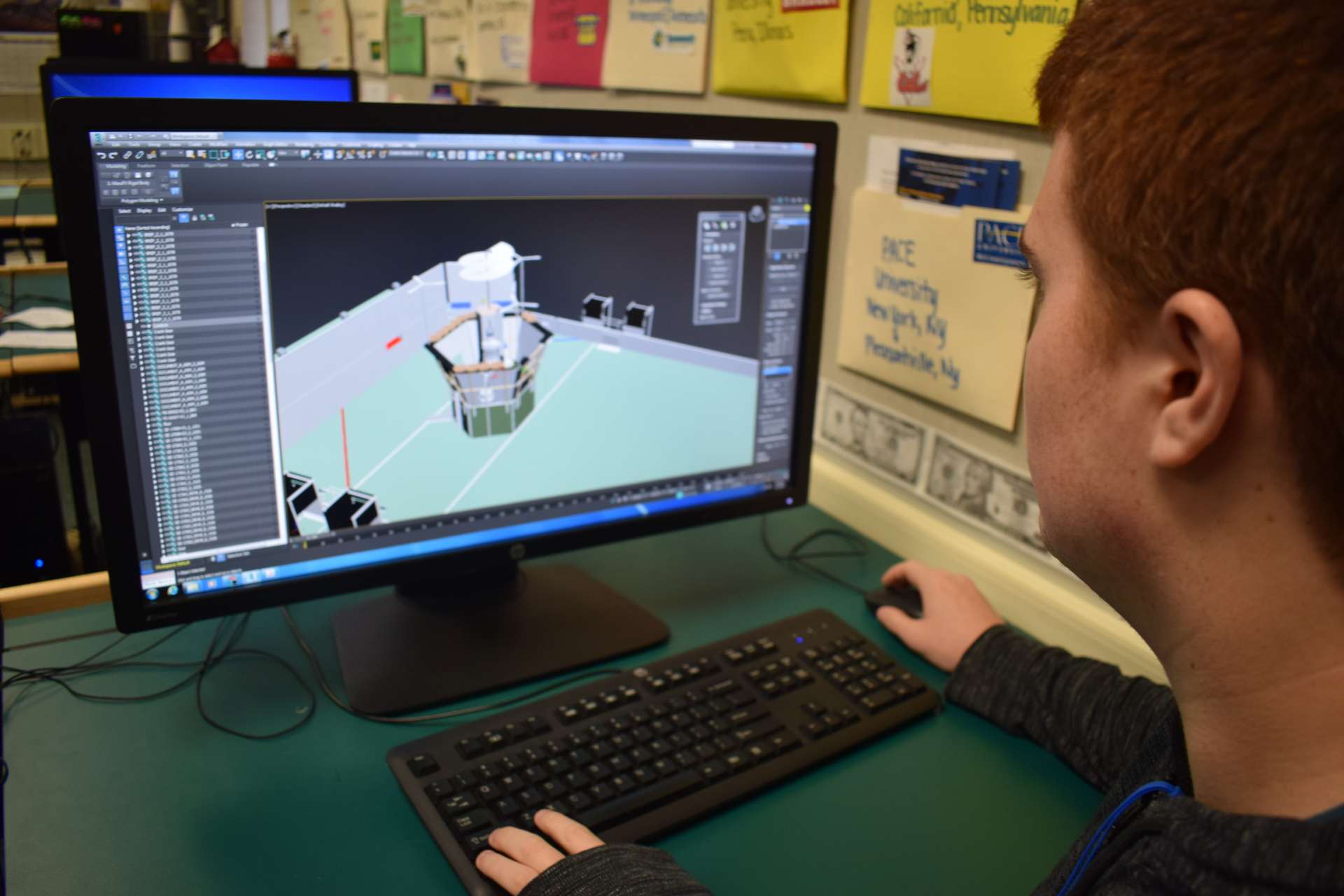

Animation

Visual masterpieces.

Team 696’s Animation Sub-Team creates high quality animations depicting various technical models. The ability to visualize certain tasks and models is a key component in our construction process.

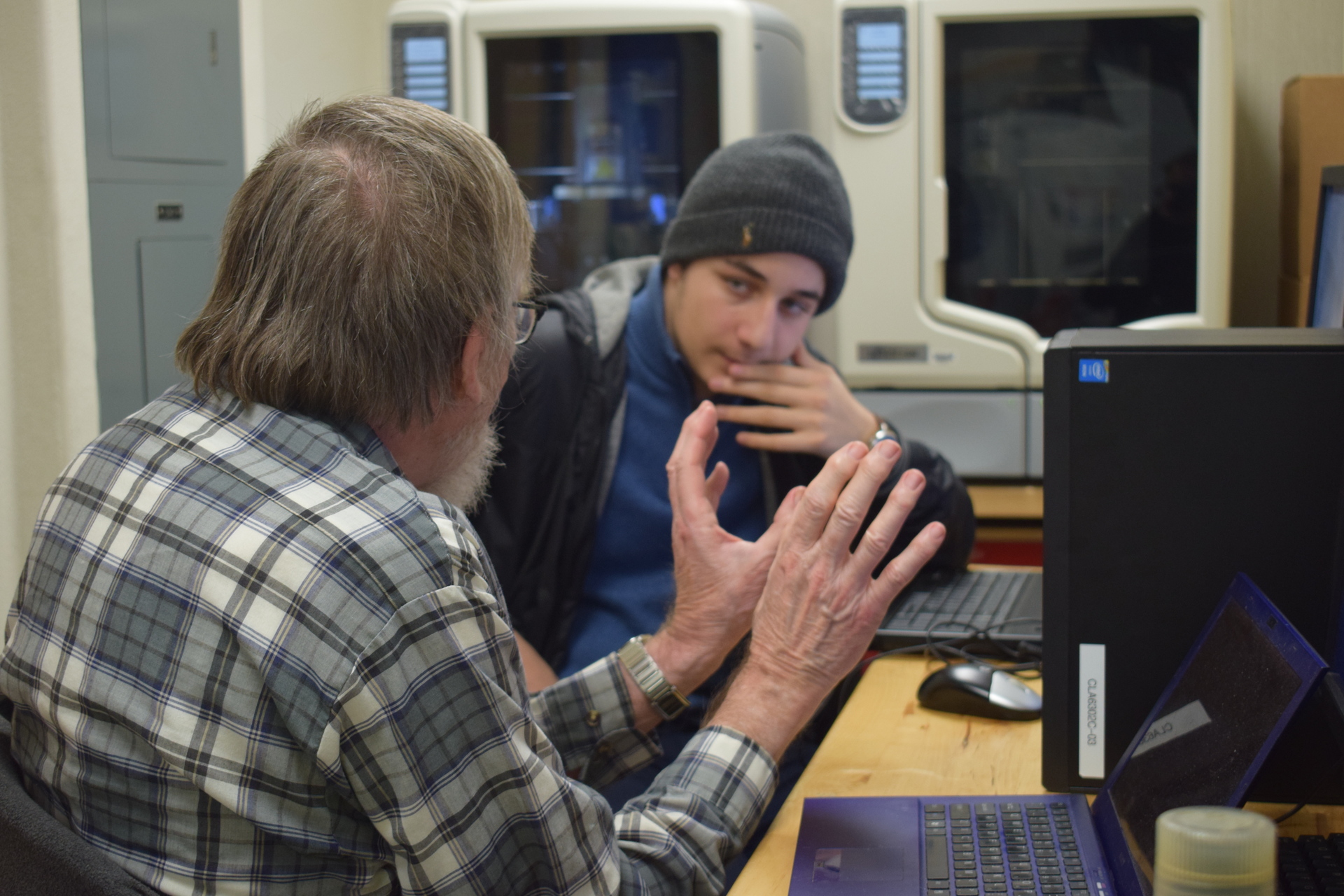

Simulation and Analysis

Real Life Simulated.

Simulation and Analysis is interconnected with almost all the subteams that work on our robot each year. Their ability to simulate mechanisms is essential to the entire design process.

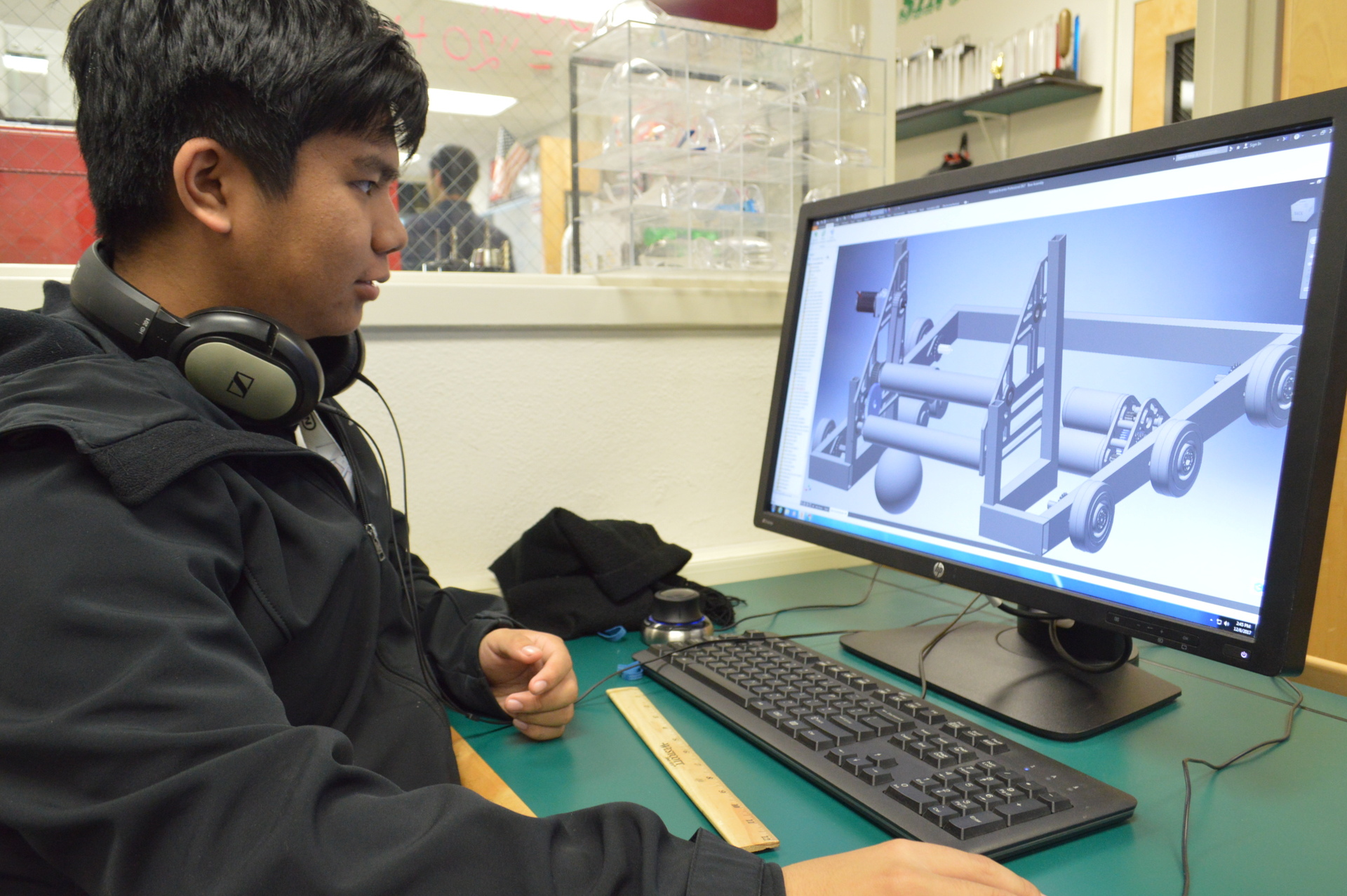

CAD

Computerized Prototyping.

A key practice within Team 696 involves the use of CAD to perfect our parts prior to machining. The CAD team ensures that we can have high quality models to predict the functionality of pieces ensuring that they are the optimal for final builds.

CAM

Sometimes you need a machine.

Life will teach you that some parts you can’t make yourself. The CAM team’s ability to program machinery to adapt to our ever-changing requests ensures Team 696 will never face this problem. They employ the use of various highly complex machinery to construct a variety of possible parts. Some of these machines include the CNC Router, Haas Mill, and Plasma Cutter.

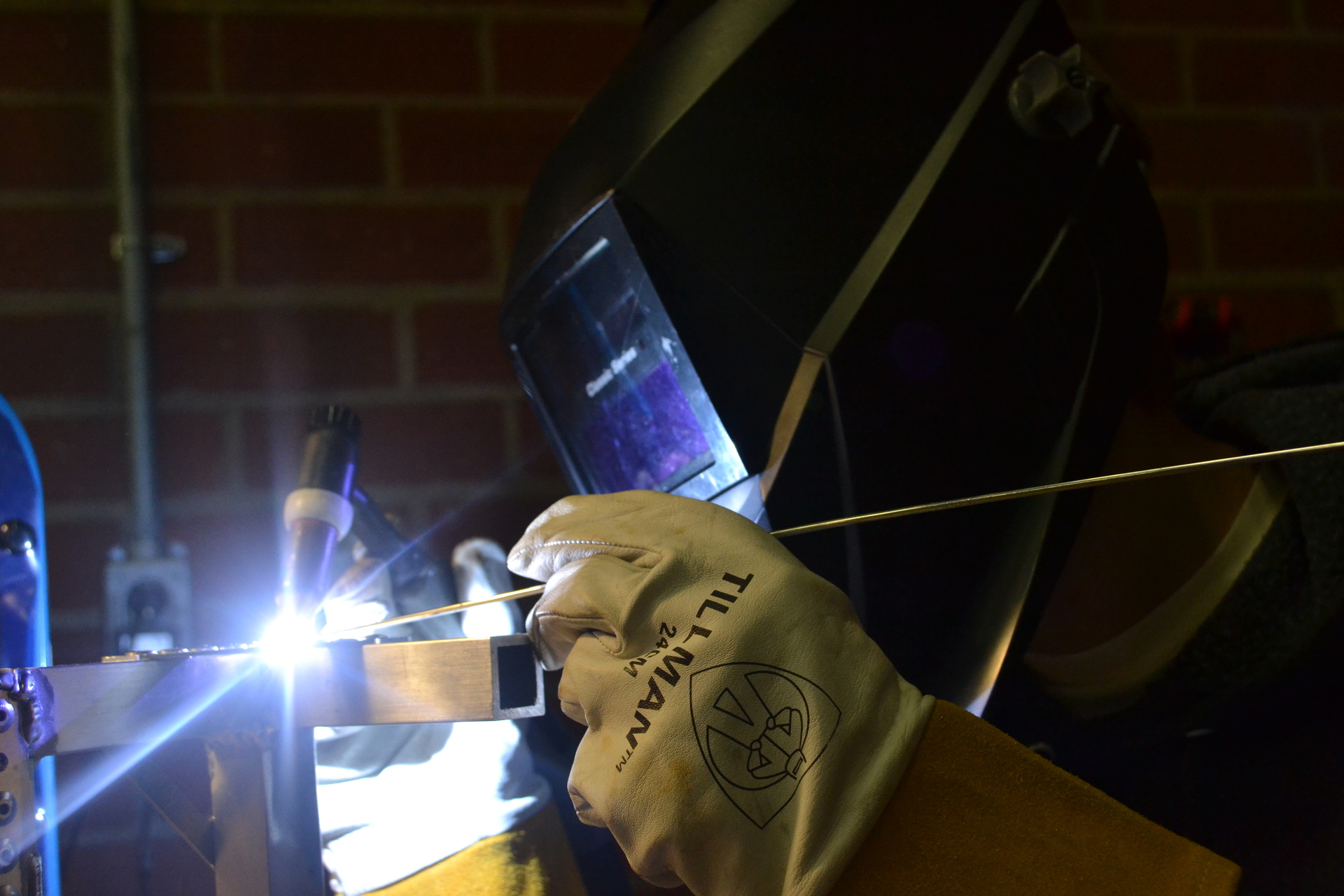

Welding

Clean and Unseen.

Our team prides ourselves on our high quality builds thanks to the large effort by our welding department. Team 696 has been a consistent contender for the Quality Award in part due to the Weldings Team's ability to create flawless welds.

Manufacturing

Machining

The product made is only as good as the work you put in. Team 696’s manufacturing team spends countless hours machining the parts that go into our builds. It is thanks to their efforts that our robot never lacks high quality parts.